Milk fat is an essential component of the flavor of milk and dairy products. It is composed of a diverse array of lipids, with over 98% being triglycerides. Additionally, it contains phospholipids, fatty acids, and sterols. The most notable characteristic of milk fat is its high saturated fat content (~60%).

The main components of fats are hydrocarbon chains. Saturated fats are those in which the carbon-carbon bonds within the hydrocarbon chains are all single bonds. Unsaturated fats, on the other hand, have double or triple bonds between carbon atoms. Most of the unsaturated fats in milk have cis structures, where the hydrocarbon chains on either side of the double bond are oriented in the same direction, resembling a “side-by-side” alignment. When there is a high proportion of saturated fats, the fats tend to clump together more densely to avoid water. Conversely, the “side-by-side” structure of unsaturated fats makes them clump together less densely.

Animal fats, such as milk fat and beef marbling, are high in saturated fats and are less able to move freely in their clumped state. In contrast, fats high in unsaturated fats, like plant oils and fish oil, are less densely packed and can move more freely. This difference in structure explains why most animal fats (except fish oil) are solid at room temperature, while plant fats are liquid. Butter is a prime example of a product that utilizes the characteristics of milk fat, which is high in saturated fat. Butter is made by separating and coagulating milk fat from cream, resulting in a solid product at room temperature that melts at 32-35°C.

Due to the high saturated fat content, milk fat has long been perceived as unhealthy. In response to these concerns, low-fat and non-fat milk options were developed. Low-fat milk typically contains 1-2% milk fat, while non-fat milk contains 0-0.5% milk fat. The process of reducing the fat content in milk involves centrifugation, a technique used in chemical experiments to separate compounds. Centrifugation involves spinning a mixture at high speed around a central axis, using centrifugal force to separate substances based on density. When milk is placed in a centrifuge, the less dense fat rises to the top and can be removed as needed to produce low-fat or non-fat milk. The removed fat is then used to produce cream and other high-fat dairy products.

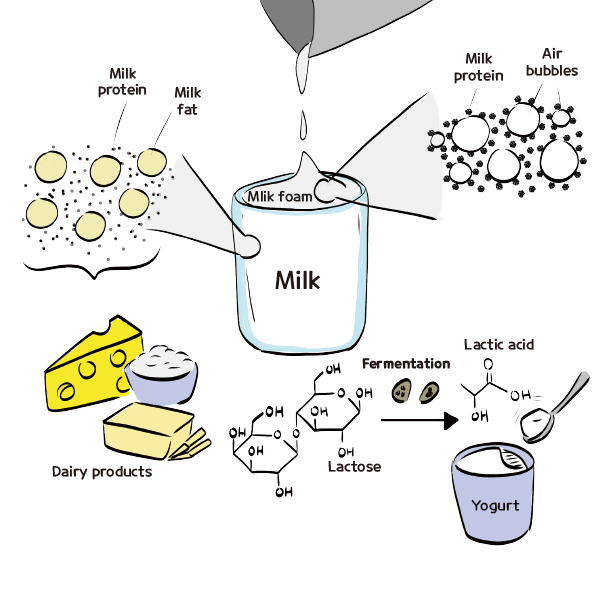

Milk fat can also form a cream layer at the top of the milk, caused by the aggregation of non-uniform fat and protein. To prevent this separation in commercial milk, the milk undergoes homogenization. This process involves applying high pressure (around 148 atmospheres) to break down the fat molecules and create a stable colloid, ensuring the fat remains evenly distributed and preventing the formation of a cream layer.

The question of whether drinking whole milk with 3.4% milk fat is worse for your health than consuming low-fat or non-fat milk is still debated. Currently, the academic consensus suggests that milk fat itself does not cause obesity or cardiovascular diseases. Some argue that the “low-fat” label might lead consumers to overconsume dairy products, inadvertently increasing their intake of sugars present in these products. Flavored milks such as chocolate, banana, strawberry, and coffee-flavored milk illustrate this concern. For example, a 300mL serving of chocolate milk contains an average of 33.5g of sugar, strawberry milk 28.7g, and banana milk 26.8g. This indicates that low-fat processed milk is not necessarily healthier.

Additionally, acidic flavors are not common in processed milk because adding acidic substances like citric acid would cause the milk proteins to coagulate. This is why you don’t find sour fruit-flavored processed milk, whereas fermented dairy products like yogurt can have such flavors since the fermentation process already involves protein coagulation due to lactic acid formation. The curd used in making mozzarella cheese, for instance, is produced by adding vinegar or lemon juice to milk, causing the proteins to coagulate.

Milk’s colloid properties, due to its proteins and fats, make it useful in various beverages. At the molecular level, milk is a solution of organic substances in water, which can be utilized effectively in different drinks. A prime example is coffee beverages like cappuccinos and lattes. These drinks feature a layer of fine milk foam on top. When homogenized milk is steamed or frothed, the colloidal particles stabilize the small air bubbles, creating a stable foam.

Proteins in milk, which are amphiphilic molecules (having both hydrophilic and hydrophobic properties, though slightly more hydrophobic), play a crucial role here. The hydrophobic parts of the protein prefer to stay with the air bubbles, stabilizing them. This property is what allows milk proteins (mainly casein) to position themselves between the air bubbles and water, creating a stable foam. This characteristic is also exploited in the production of whipped cream, heavy cream, and ice cream. The smooth texture of cream is due to the reduced density sensation from the fat and protein colloids that create foam.

I’ve already mentioned several times in the process of explaining the characteristics of milk about fermented milk (yogurt) made from milk. Yogurt is made by fermenting milk with lactic acid bacteria. Fermentation is a metabolic process in which microorganisms break down sugars without oxygen to obtain energy, which is essentially the same as decay. However, when it does not harm humans, it is called fermentation, and when it becomes a state with strong odor and toxicity, it is called decay. A key factor in distinguishing between fermentation and decay is the type of microorganism. Yogurt is produced with lactic acid bacteria, a category of probiotics. During the fermentation process, the sugars in the milk are oxidized into lactic acid, giving it a sour taste, and the colloid components are thickened by lactic acid, increasing the viscosity.

You can find yellow-colored “Yakult,” a fermented beverage, in a grocery store next to the yogurt session (Especially in an Asian Mart). The difference between fermented milk, called yogurt, Yakult can be thought of as similar to original and imitation products. Yakult is not fermented directly from milk, but powdered skim milk (milk from which fat has been removed and dried) is fermented in water containing sugar and high-fructose corn syrup. Instead of sugars, such as lactose in milk, sugar and fructose are artificially added for fermentation, allowing both sweet and sour tastes to coexist without thickening of milk protein. It was first produced and introduced in Japan in the 1930s as a fermented beverage popular among Asians unfamiliar with fermented milk products. Its tangy-sweet taste has spread beyond Asia to various parts of the world, and it is also sold as a beverage with various fruit flavors. Yakult also contains plenty of lactic acid bacteria. Conversely, fermented milk products such as yogurt also contain high amounts of sugars. For example, a 300 mL (10 oz) product contains 20-38 g of sugar. In terms of sugar content alone, it is not much different from sodas or fruit juices.

References

- Bhat et al., (2016) ‘Casein Proteins: Structural and Functional Aspects’ in Milk Proteins – From Structure to Biological Properties and Health Aspects, IntechOpen

- Rashidinejad et al. (2017) ‘Nutrients in Cheese and Their Effect on Health and Disease’ in Nutrients in Dairy and their Implications on Health and Disease, Academic Press, an imprint of Elsevier

- Truswell, Eur. J. Clin. Nutr. 2005, 59, 623

- Thalheimer, Today’s Dietitian, 2017, 19, 10

- Jesnsen et al. Dairy Sci, 1991, 74, 3228

- http://www.seoulmilkblog.co.kr/

- Weinberg, J. AM. COLL. CARDIOL., 2004, 43, 731

- Elhauge, Eur. J. Clin. Nutr., 2018, 72, 249

- https://www.yakult.co.jp/

Leave a comment